maximize tire + equipment life

a proactive rescue mission

We all hate sudden repair costs, and for fleet vehicles, it can mean devastating revenue losses as well. A comprehensive maintenance plan comes to the rescue, proactively preventing much of the unscheduled maintenance vehicles go through during their lifetime. Investing in a Mobalign fleet commercial alignment program could provide savings in fuel and tires of hundreds if not thousands of dollars per vehicle. This is why fleet managers and owner operators trust Mobalign as their partner in fleet maintenance.

maximize tire + equipment life

a proactive rescue mission

We all hate sudden repair costs, and for fleet vehicles, it can mean devastating revenue losses as well. A comprehensive maintenance plan comes to the rescue, proactively preventing much of the unscheduled maintenance vehicles go through during their lifetime. Investing in a Mobalign fleet commercial alignment program could provide savings in fuel and tires of hundreds if not thousands of dollars per vehicle. This is why fleet managers and owner operators trust Mobalign as their partner in fleet maintenance.

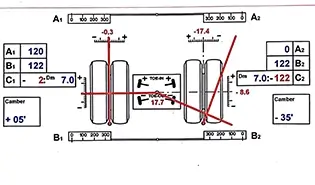

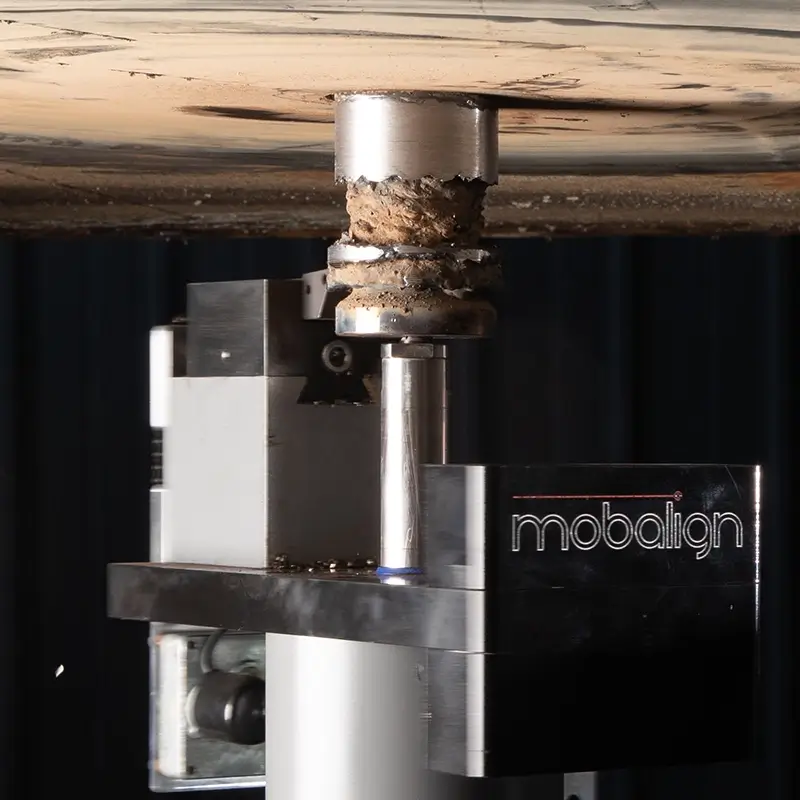

laser-focused, onsite wheel alignments

We provide the most advanced laser alignment available, right on the customer premises. Our system communicates any issues such as worn components which may affect the quality of alignment. This goes beyond a traditional commercial truck alignment, uncovering issues that may otherwise go unnoticed—until the inevitable breakdown of crucial components later down the road.

identify problems beyond alignment

identify

problems

beyond alignment

laser-focused, onsite wheel alignments

We provide the most advanced commercial truck laser alignment available, right on the customer premises. Our system communicates any issues such as worn components which may affect the quality of alignment. This goes beyond a traditional alignment, uncovering issues that may otherwise go unnoticed—until the inevitable breakdown of crucial components later down the road.

tire & fuel savings

an “insurance policy” for your fleet

You’re insuring against:

Excessive tire wear

Fuel inefficiency

Driver fatigue

Equipment component wear

tire & fuel savings

an “insurance policy” for your fleet

You’re insuring against:

Excessive tire wear

Fuel inefficiency

Driver fatigue

Equipment component wear