Introduction

Managing a fleet of trailers while ensuring operational efficiency, safety, compliance, and profitability in today’s commercial trucking industry presents a unique set of challenges for fleet managers. To have a positive impact on the total cost of ownership (TCO) requires proactive maintenance strategies that can involve innovative repair solutions that increase the lifespan of equipment while reducing downtime.

One strategy is to implement a trailer kingpin refurbishing program.

In this article we’ll explore the pivotal moments when you should consider repairing your trailer’s kingpin, looking into the details of wear standards, inspection techniques, and more.

Understanding the Trailer Kingpin

The kingpin is a solid steel pin that’s integral to the structure of a trailer. Located at the front of a semi-trailer, it connects to the fifth wheel on a hauling truck, playing a key role in trailer stability and maneuverability. Over time, frequent use and harsh driving conditions can wear down this vital component. Understanding the early signs of wear and how they impact your trailer’s performance is key to proactive maintenance.

Minimum wear standards

So, what exactly constitutes too much wear? According to most manufacturers and the Department of Transportation (DOT), the kingpin should not exhibit more than a specified percentage of wear – typically around 1/8th inch from its original diameter. This standard ensures that the kingpin remains functional and safe. Regular measurements and comparisons against these standards are vital in deciding when to initiate repair procedures.

kingPIN and bolster plate inspections

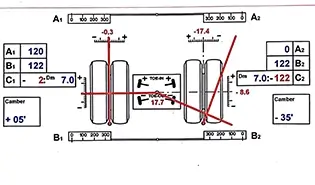

An effective kingpin inspection involves more than a cursory glance. Start by examining the kingpin for visible signs of wear, distortion, or cracking. Don’t overlook the bolster plate – the area surrounding the kingpin. This plate should be flat and intact without any warping, bending, or minimal warpage that could indicate hidden structural problems. Implementing a rigorous inspection schedule at agreed intervals recommended by your trailer manufacturer helps in early detection of potential issues.

Acting as a predictive maintenance partner, Mobalign offers free trailer audits providing fleet managers with a report detailing the condition of their kingpins and bolster plates, indicating which trailers are eligible for a kingpin refurbishment. This enables the fleet manager to plan for repairs in batches of trailers working within their maintenance budgets.

additional factors to consider

Road Conditions and Usage: Heavy-duty hauls and adverse road conditions can fast-track the wear and tear on a kingpin. If your routes involve rough terrains, frequent starts and stops with decoupling, or harsh environmental conditions, increasing the frequency of your inspections is a wise move.

Legal and Safety Implications: Ignoring kingpin wear isn’t just a risk to your operations; it’s a legal liability. Operating with a worn or damaged kingpin can lead to failed inspections, hefty fines, or worse – severe accidents. The safety of the driver, the load, and everyone on the road hinges on this small but mighty component.

cost of repair vs. replacement

Refurbishing a worn kingpin is significantly more economical than full replacement. This is due to a reduction in downtime as the repair can be performed at the customer location fitting in with the fleet manager’s schedule and to the fact that new parts are not purchased. However, this decision should be based on professional assessments. Factors like the extent of wear, integrity of the bolster plate, and budgets should be considered. In many cases, a refurbished kingpin can outlast a newly replaced kingpin.

kingpin repair process

The repair process typically involves assessing the extent of wear of the pin and bolster plate, followed by welding and precise machining to restore the kingpin to its original standards. Selecting an experienced service provider, such as Mobalign, ensures that your trailer is in capable hands. Expert technicians equipped with the right tools can extend the life of your kingpin, ensuring safety and compliance.

conclusion

Regular inspection and maintenance of your trailer’s kingpin are not just best practices; they’re essential for safe and efficient operations. By adhering to minimum wear standards and understanding when to opt for repairs, you can ensure that your trailer fleet remains compliant while minimizing the total cost of ownership. Remember, the cost of neglecting your kingpin can be far greater than the expense of maintaining it.

With years of experience in the industry, Mobalign is a trusted name in trailer kingpin repairs.

Our expertise is one of the main reasons to choose Mobalign for your kingpin repair needs. Our team of skilled technicians has extensive knowledge of trailer systems and can accurately diagnose and refurbish your kingpin. We understand the importance of a properly functioning kingpin in ensuring the safety and stability of your trailer.

Additionally, Mobalign is committed to providing excellent customer service and is dedicated to meeting your specific needs. We understand that time is of the essence when it comes to getting your trailer back on the road and can work within your schedule.

Contact us today for your trailer kingpin repair.

additional resources

For more insights into kingpin maintenance and repair, check out this page. Don’t hesitate to get in touch with us for personalized consultation and expert service solutions tailored to your needs. Remember, when it comes to your kingpin, it’s better to be safe than sorry!