Trucks work hard. Spindles take a lot of that stress. When they fail, you need a reliable repair that gets your fleet moving again—quickly.

Mobalign—the leading on-site, specialized repair company for the commercial trucking industry—offers professional spindle repair services designed to maximize uptime and minimize disruption. Our advanced method allows us to repair drive and trailer axle spindles at your location with no axle removal required.

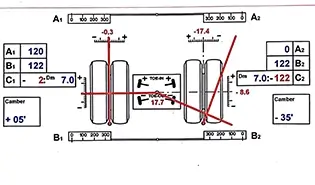

Over the years, Mobalign has used systems for other service providers; however, we found flaws, and our advanced laser alignment system confirmed that these systems were not accurate. As specialists in alignment and being known for precision, we had no choice but to develop our system.

This blog post explores why spindle condition is vital, how to spot early signs of wear, and how our mobile repair services keep your fleet operating safely, efficiently, and on schedule.

Why Spindles Matter in Fleet Safety and Performance

Keeping drive and trailer axle spindles in good condition is essential to fleet safety and reliability.

One critical reason? Operator safety. A damaged or failing spindle can lead to dangerous consequences like wheel separation or loss of vehicle control—risks no fleet can afford to ignore. Because the spindle connects the hub and bearing assembly, its failure under load or speed can cause sudden downtime, expensive roadside repairs, or worse, a collision. That’s why early detection and proper repair aren’t just maintenance—they’re critical.

Why Professional Spindle Repair Matters

Spindle issues aren’t just mechanical—they’re safety concerns. In high-stakes fleet operations, trusting your repairs to experienced professionals can mean the difference between seamless logistics and unplanned shutdowns.

Mobalign spent 10 years exploring various methods and processes for repairing spindles. One of our primary concerns was to ensure the most accurate alignment system possible. After using our advanced alignment method to measure repairs done by others, we found inaccuracies due to misalignment of the spindle up to 7/16” (11mm). That level of inaccuracy can result in approximately 55 feet of scrub per mile in the forward direction. The accuracy of the Mobalign system eliminates this issue by ensuring precision alignment every time.

At Mobalign, our technicians are evaluated, trained, and certified through rigorous internal programs that cover safety, theory, welding, and field performance. Our work is guided by our core values of excellence, innovation, and integrity, and our technicians undergo ongoing evaluations to maintain the highest standards in every job.

We serve a wide range of industries, including:

- Long-haul transport

- Fuel and gas

- Concrete and gravel

- Municipality fleets

- Logging and waste disposal

- Fire & rescue and military sectors

Because of these risks, having a trusted repair partner like Mobalign is essential. Here’s why professional spindle repair matters.

5 Signs You May Need Drive Axle/Trailer Axle Spindle Repair

Staying ahead of spindle damage is key to preventing unexpected repairs and keeping vehicles in service. Watch for these warning signs:

- Visible cracks, rust, or deformation on or around the spindle

- Hub Seal leaks

- Excessive wheel bearing end play

- Spindle surface wear (bearing & seal surfaces)

- Accident/impact damage

If you observe any of these symptoms, prompt inspection and repair are essential. Delaying action puts vehicles and drivers at risk and increases long-term maintenance costs.

Mobalign’s On-Site Spindle Repair Services: How It Works

Mobalign repairs spindles directly at your facility. Our certified technicians employ advanced welding and spindle installation techniques to provide precise, durable repairs with minimal disruption.

What makes our process different:

- No axle removal required

- Drive and trailer axle spindles repaired on-site

- Fast return to service

- Certified technicians trained at Mobalign facilities are experienced with waste disposal, military, and courier services

- Field-tested repair methods for lasting performance

What Makes Mobalign Different

At Mobalign, we don’t just perform repairs—we partner with our clients to deliver sustainable solutions. Our team collaborates with fleet managers to develop alignment and repair programs that prevent issues before they arise. Through our consultative approach, we help reduce tire wear, fuel consumption, and downtime costs—making us a long-term partner in your success.

What sets us apart:

- The most comprehensive laser alignment service in the industry

- Customer-centric scheduling—we work around your operations

- Practical education around tire selection, rotation, and inflation

When uptime matters, Mobalign combines expertise, speed, and precision to reduce costly delays and keep operations moving.

Prevent Downtime, Protect Your Fleet

A single compromised spindle can derail a delivery schedule, increase safety risks, and trigger a cascade of costly repairs. When a spindle fails, it’s more than a mechanical issue—it disrupts your business.

Mobalign offers a specialized on-site repair service that’s fast, precise, and designed for today’s high-demand fleet operations. Our proven process eliminates the need for axle removal and helps minimize vehicle downtime so trucks return to service efficiently and safely.

If you see signs of spindle wear or damage, don’t wait until it sidelines your equipment. Contact Mobalign today to schedule expert mobile spindle repair at your facility—and learn more about our full range of services, including laser wheel alignment, trailer kingpin repair, and rear axle repair.